Raudel Arteaga makes shoes that don’t exist: the pillowy Hoka Bondi 5 sole paired with Nike’s sock-like Flyknit Racer upper, or an original Adidas UltraBoost 1.0 knit with the new honeycomb sole of an Adidas 4D. They come from the imaginations of sneakerheads dreaming up new styles, and inventive runners in search of their ideal shoe. If the parts are out there, Arteaga will fuse them into the hybrid sneaker of their dreams.

Arteaga’s shoe mash-ups started as a side hustle when he was an art student trying to afford paint and supplies. But in three quick years, the business has grown into Govrn, a five-person studio outside Los Angeles, fielding custom requests from around the world to seamlessly combine the best parts of a client’s favorite street or athletic shoes.

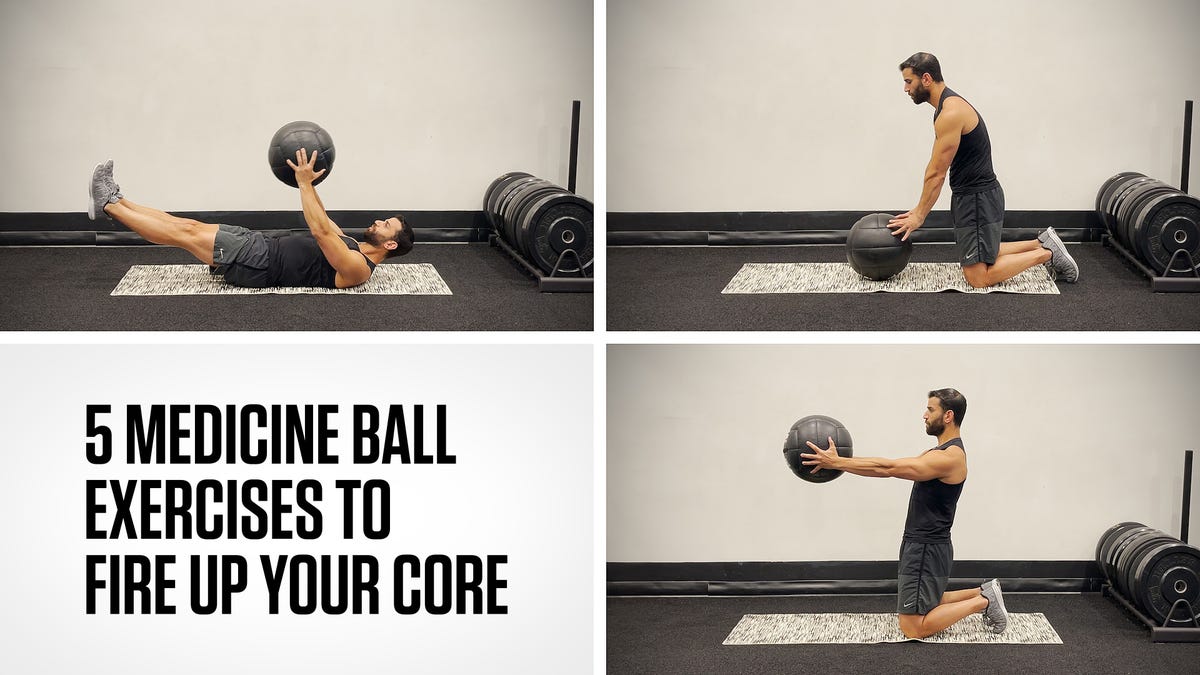

Runner’s World visited Arteaga’s original home workshop, where he shared his process and insights on what runners really want from their shoes.

How long does each pair of shoes take?

I work in batches where it’s two to three days to complete each pair. But if I were to focus on one pair, I could do a pair a day. It used to take two or three. It actually feels like meditating. You start focusing on the smallest detail. It’s such high stakes that an hour will pass by and I didn’t feel it at all. The hyper-attentiveness actually clears my mind.

You’re a sneakerhead, but how did you get into running shoes?

When I started, I didn’t have a focus on athletic wear. But in the first year, the Nike Flyknit Racers with the Nike Lunarlon sole were order number one. As many as 80 pairs. I have a couple of the Flyknit Lunars myself. I started making them for other people and thought they looked very comfortable, something you could wear in the summer. It’s not only a beautiful design for an everyday shoe, but it’s very functional.

And then once the Vaporfly was released, a lot of people wanted a Vaporfly sole with different models on top. Like a Pegasus 35, it’s waterproof. The Vaporfly doesn’t come in waterproof, but a client wanted that, so we made it.

The inspiration comes from companies that design special shoes for [pro] runners. But Nike, Adidas—they won’t do that for just anyone.

How has your process evolved?

My first shoe hybrid, I was trying to pull apart these Nike AirMax 90s. One way that I’ve seen people separate shoes is through boiling hot water. I’d boil the water on the stove and pour some inside the shoe where you’d put your foot in. Once the heat hits the adhesive, it’s easier to pull apart. But I kid you not, one pair took me an hour to separate.

When I started working, I was actually using our kitchen oven. You can put the shoe in there, and it will heat up the adhesive. It will get hot enough that it’s a lot easier to pry apart. I’ve moved on to using a heat gun and now a thermal oven. And I don’t work from home anymore.

After you’re able to pry it, we use a solution that will break down the compound a little bit more. Then we make sure all the residue that was originally there is gone. Leather is really easy to clean through dremeling or sanding. We also sand areas that had not been sanded before, which helps our adhesive stick. We have to make sure the pieces are super ready for bonding.

After the adhesive, we put it on the press, make sure it’s lined up, and press it together. We do a check to make sure everything is fully sealed through. And another touch of adhesive around to seal it.

Are you wearing a mashup right now?

Yeah, I’m wearing a hybrid pair of slippers I made. It’s a memory foam slipper with an Air Zoom basketball shoe sole. My dad wanted a pair of slippers he could go out and water the lawn in. They’re really comfortable. So, I made a pair for myself.

Can you walk us through this Adidas hybrid?

This Adidas hybrid’s UltraBoost upper is a caged, knitted shoe—great comfort. The 4D sole has strength, comfort, and an appealing design quality. Instead of leaving the original black rubber outsole on the 4D, we decided to use the UltraBoost’s red Continental outsole. Not only is it a great color, but it has better grip with the Continental rubber.

The 4D is a relatively simple shoe. It’s made out of a harder material, which makes separating it pretty routine. It’s the softer materials in the midsole that can create problems: easier to tear, easier to get stuck in the upper. Under heat, the Lunarlon foam can get marshmallowy

and sticky.